Turbine Flow Sensor: Technology and Applications

2024/8/15 10:46:40

Views:

A turbine stream sensor could be a gadget utilized to degree the stream rate of fluids or gasses in a pipeline. Its rule is based on recognizing the turn of turbine edges driven by the liquid or gas to produce signals. When the medium streams through the pipeline, the turbine edges are driven by the medium, causing them to pivot and produce a recurrence flag corresponding to the stream rate. By recognizing and handling these signals, the stream rate of the medium can be decided. Turbine stream sensors regularly incorporate a sensor portion and a flag handling portion, appropriate for measuring the stream rate of diverse sorts of media.

Center Working Instrument of Turbine Stream Sensors

The working guideline of a turbine stream sensor can be summarized within the taking after steps:

Medium drives turbine edges to turn: When fluid or gas passes through the pipeline, the stream of the medium drives the turbine edges to begin pivoting.

Recurrence flag era: The rotational speed of the turbine edges is closely related to the stream rate of the medium, and this rotational movement produces a recurrence flag corresponding to the stream rate.

Flag location and recording: The sensor precisely identifies the rotational recurrence of the turbine edges and records these recurrence signals.

Signal processing and analysis: The signal processing unit analyzes and converts the detected frequency signals, ultimately obtaining data reflecting the flow rate.

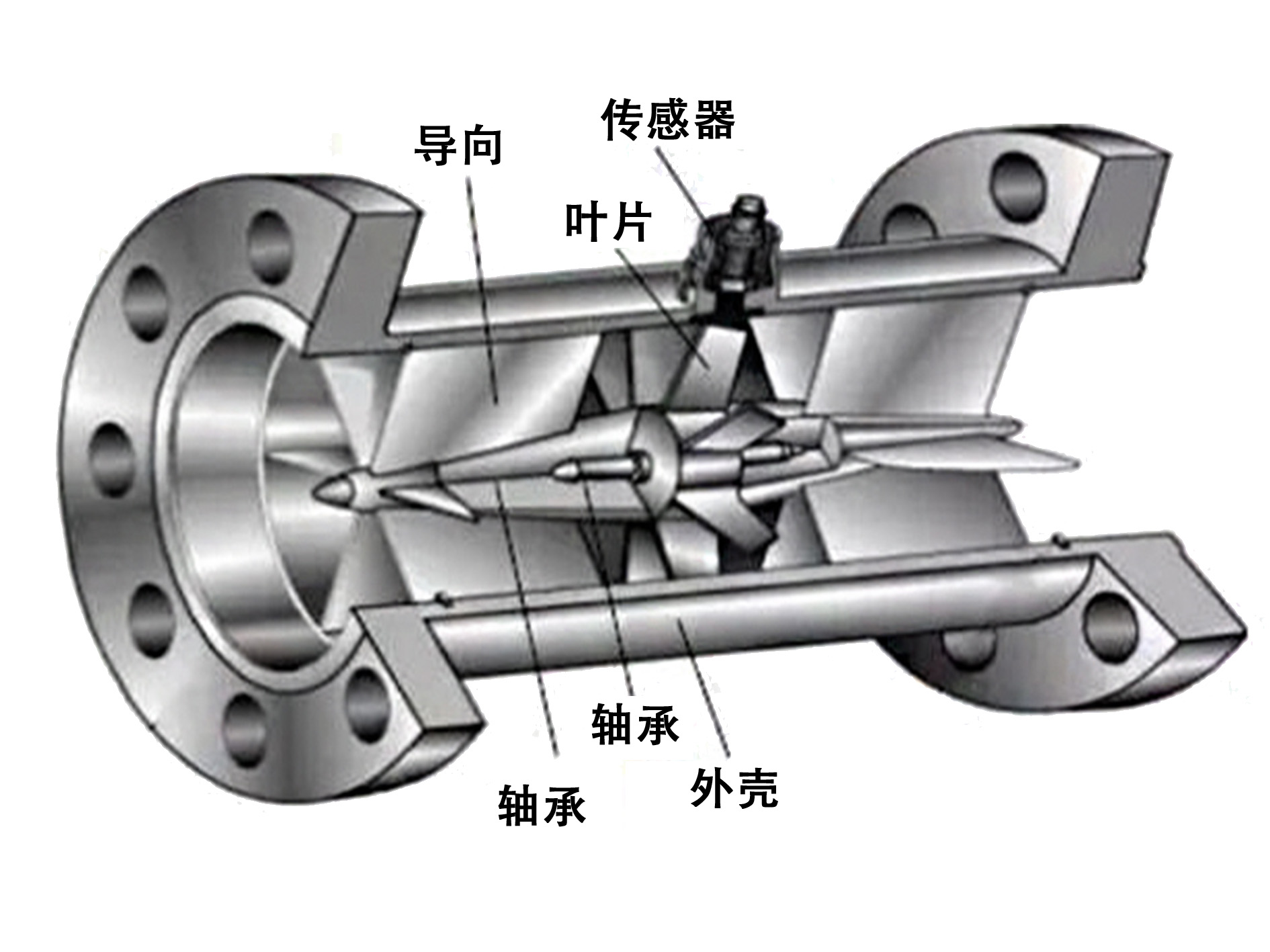

Structural Components of Turbine Flow Sensors

Structural Components of Turbine Flow Sensors

The fundamental components of a turbine stream sensor are as takes after:

Turbine edges: Found within the fluid or gas channel, the turbine edges are driven to pivot when the medium streams through.

Flag location sensor: Utilized to distinguish the recurrence flag created by the revolution of the turbine edges.

Signal processing module: Processes the signals from the sensor and converts them into flow rate data.

External casing: Protects and supports the entire device, preventing external environmental influences on the internal structure.

Connecting pipeline: Connects to the main pipeline to ensure that the medium can smoothly pass through and drive the turbine blades to rotate.

Main Advantages of Turbine Flow Sensors

Compared to other types of flow measurement devices, turbine flow sensors have the following notable advantages:

High precision: It has high measurement accuracy and can accurately detect the flow rates of various media.

Wide measurement range: Suitable for various flow rate measurement needs, covering a wide range of measurements.

Strong stability: Maintains stable accuracy after long-term use with almost no degradation.

Quick reaction: Rapidly reacts to changes in stream rate, appropriate for real-time checking.

Erosion resistance: Great erosion resistance to destructive media, appropriate for unforgiving mechanical situations.

Simple establishment and upkeep: Basic basic plan, simple establishment, moo support costs, and long benefit life.

Application Areas of Turbine Stream Sensors

Turbine stream sensors are broadly utilized in different mechanical areas, counting but not restricted to the taking after:

Chemical industry: Utilized to screen the stream rates of different fluids and gasses in chemical forms, guaranteeing exact control of generation forms.

Petroleum industry: Utilized to screen the stream rates of rough oil, characteristic gas, and other media in oil extraction, transportation, and handling.

Pharmaceutical industry: Reasonable for observing the stream rates of fluids and arrangements in pharmaceutical forms, guaranteeing generation quality and security.

Nourishment industry: Utilized to screen the stream rates of fluid nourishment in nourishment handling, guaranteeing item quality.

Water treatment systems: Used in water supply and wastewater treatment to monitor water flow rates, ensuring the rational use of water resources.

Energy industry: Widely used in thermal power plants, nuclear power plants, and other energy facilities for flow monitoring.

Summary and Outlook

Turbine flow sensors, with their high precision, fast response, and stability, are increasingly being applied in modern industries. As innovation proceeds to progress and application scenarios extend, these sensors will assist optimize their execution and play a key part in more assorted areas.

Within the future, with the advancement of IoT and keen fabricating innovations, turbine stream sensors are anticipated to coordinated with other keen gadgets to realize more exact and proficient stream observing and administration. This will not as it were offer assistance move forward the effectiveness and security of industrial production but too drive the brilliantly change of the whole industry, laying the establishment for the entry of the Industry 4.0 time. In this setting, turbine stream sensors are beyond any doubt to play an progressively imperative part in future mechanical applications.

Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp