Innovative applications of reversible motors in the field of new energy

2024/7/29 14:26:39

Views:

Reversible engines are a sort of engine that can turn in both forward and switch headings and can switch between engine and generator states. This article will investigate its standards and applications in profundity.

I. Structure of Reversible Motors

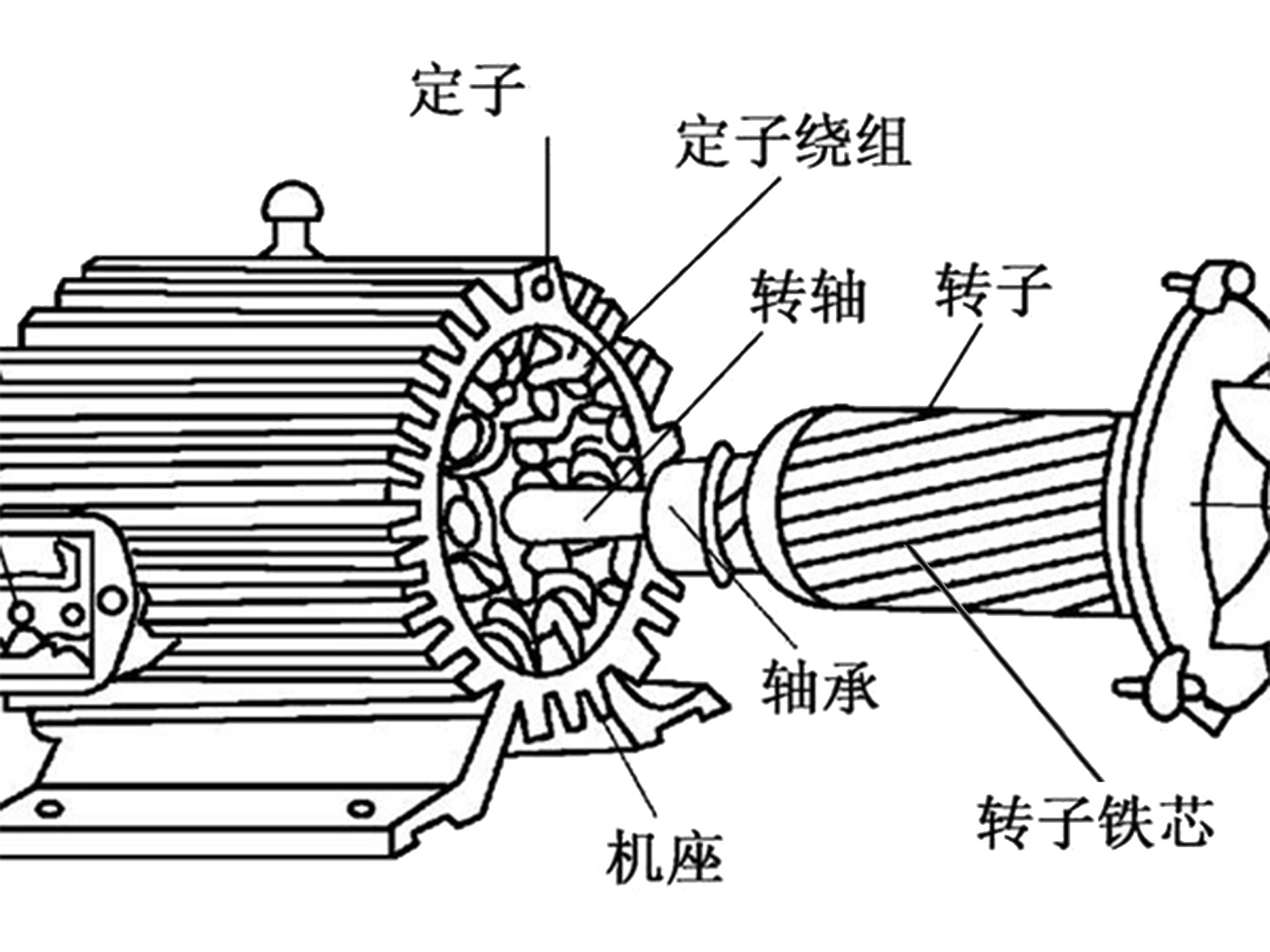

By and large fueled by a DC control source, reversible engines comprise of a stator and a rotor. The stator contains an press center and coils, whereas the rotor incorporates an press center and windings. The crevice between the stator and rotor transmits control through electromagnetic interaction.

Structure of a reversible motor

II. Working Principle of Reversible Motors

Based on the law of electromagnetic acceptance, when a DC control source is associated to the stator coil, it produces a attractive field that interatomic with the rotor coil to create electromagnetic constrain. When the electromagnetic drive equalizations with the rotor's dormancy, the rotor remains steady. When the rotor's heading changes, the attractive field heading within the stator coil too changes in like manner, generating an inverse current within the rotor coil to counterbalanced the stator coil's attractive field, hence changing the rotor's heading.

III. Applications of Reversible Motors

1. Motor and Generator States

Motor state: Used as a motor to drive the rotor rotation.

Generator state: Used as a generator to convert mechanical energy into electrical energy.

2. Industrial Automation

Drives robotic joints on production lines for automated assembly.

Drives conveyor belts in logistics lines for automated transportation of goods.

3. New Energy

Wind power generation: Converts wind energy into electrical energy and stores it.

Electric vehicles: Drives the vehicle and recovers braking energy.

4. Other Industrial Applications

Printing, packaging, metallurgy: Enables quick conversion of production lines and process changes. Drives suction cups on packaging machines to move products, opens and closes furnace doors, and elevates material carts in the metallurgy industry.

IV. Advantages of Reversible Motors

1. Bidirectional operation: Suitable for equipment and mechanical systems requiring forward and reverse operations.

2. Simplified control system: No additional devices or mechanisms needed to change direction, simplifying control design, reducing costs, and improving reliability.

3. Optimized space and cost: Replaces dual unidirectional motors with one reversible motor, significantly reducing the number of devices and occupied space.

4. Simplified maintenance and repair: Only one motor to maintain, reducing complexity and cost, and improving reliability and durability.

V. Limitations

In specific applications, higher output power or torque may be required, which a single reversible motor might not meet. Additionally, some scenarios require more precise control and adjustment, and the control performance of reversible motors may be relatively lower.

Conclusion

Due to their bidirectional operation, simplified control systems, space and cost savings, and simplified maintenance, reversible motors are widely used in fields requiring bidirectional movement and simplified control systems. With the continuous development of industrial automation and new energy technologies, the application prospects of reversible motors are becoming increasingly broad.

Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp