Unveiling the secrets of power module ripple and noise testing: methods and engineering applications

2024/5/25 11:19:03

Views:

The ripple and noise test of the power module is a crucial part of the power module test, because ripple and noise will directly affect the performance and stability of the device. By performing power ripple and noise tests, the ripple of the power supply can be detected, thereby improving the performance of the power supply. Nanosoft's power module test system can help perform ripple and noise tests and improve test efficiency.

Power module ripple and noise test method

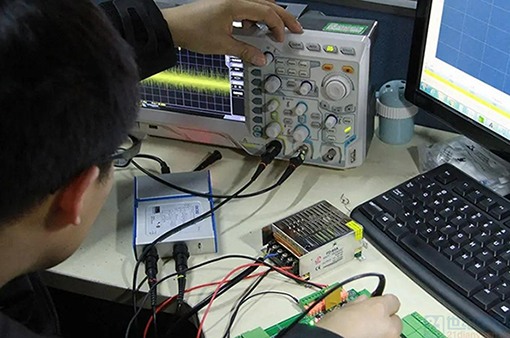

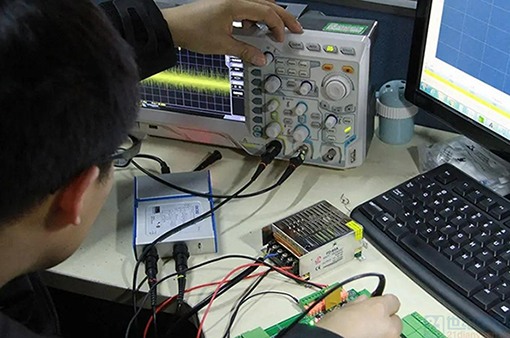

Ripple and noise test is used to detect the ripple and noise of the DC output voltage. Generally, the standard for these ripples and noise is less than 1% of the output voltage. When testing, AC power supply, electronic load, oscilloscope and temperature control room and other test equipment are required.

Test conditions include various input voltages, output loads and temperature conditions. Before testing, it is necessary to set the output parallel filter capacitor specified by SPEC and the bandwidth limit, which is usually 20MHz. In addition, it is also necessary to avoid the noise caused by the interference of the oscilloscope probe itself.

The test method includes connecting various test instruments, equipment and the product to be tested, and then testing the ripple and noise of the power supply under various conditions.

Switching power supply ripple and noise test

Advantages of power module test system

1. Various instrument instructions are encapsulated, which can quickly build the process flow and improve the construction speed.

2. Strong compatibility, can test other power indicators besides ripple and noise, and is compatible with more than 2,000 test instrument models.

3. Support remote control and support a variety of programmable interfaces, including RS232, LAN, USB and GPIB. This means that the test can be carried out anytime and anywhere, and the test data can be monitored on the mobile terminal.

4. Support batch testing and multi-station expansion, which can greatly improve the test speed.

5. Powerful data processing function, can automatically collect, summarize and analyze test data, and present it in the form of charts. Data reports can also be generated and exported, with various report templates, which can be selected as needed.

Risks associated with ripple

Ripple will cause equipment damage, disrupt circuit logic, produce surge voltage or current, and lower power supply efficiency. Therefore, when making a power supply, the ripple needs to be reduced to a smaller level.

Identifying a single power supply and debugging measurement of the product are the two general categories into which power supply ripple measuring techniques fall.

When conducting power supply identification, it is necessary to choose to test in a suitable environment to ensure that the test results are accurate and reliable.

The filtering efficiency of the DC power supply, or ripple factor, can be assessed using the effective value of the ripple voltage and the percentage of the DC output voltage. The ripple factor is an important indicator for evaluating DC power supplies.

Power module ripple and noise test method

Ripple and noise test is used to detect the ripple and noise of the DC output voltage. Generally, the standard for these ripples and noise is less than 1% of the output voltage. When testing, AC power supply, electronic load, oscilloscope and temperature control room and other test equipment are required.

Test conditions include various input voltages, output loads and temperature conditions. Before testing, it is necessary to set the output parallel filter capacitor specified by SPEC and the bandwidth limit, which is usually 20MHz. In addition, it is also necessary to avoid the noise caused by the interference of the oscilloscope probe itself.

The test method includes connecting various test instruments, equipment and the product to be tested, and then testing the ripple and noise of the power supply under various conditions.

Switching power supply ripple and noise test

Advantages of power module test system

1. Various instrument instructions are encapsulated, which can quickly build the process flow and improve the construction speed.

2. Strong compatibility, can test other power indicators besides ripple and noise, and is compatible with more than 2,000 test instrument models.

3. Support remote control and support a variety of programmable interfaces, including RS232, LAN, USB and GPIB. This means that the test can be carried out anytime and anywhere, and the test data can be monitored on the mobile terminal.

4. Support batch testing and multi-station expansion, which can greatly improve the test speed.

5. Powerful data processing function, can automatically collect, summarize and analyze test data, and present it in the form of charts. Data reports can also be generated and exported, with various report templates, which can be selected as needed.

Risks associated with ripple

Ripple will cause equipment damage, disrupt circuit logic, produce surge voltage or current, and lower power supply efficiency. Therefore, when making a power supply, the ripple needs to be reduced to a smaller level.

Identifying a single power supply and debugging measurement of the product are the two general categories into which power supply ripple measuring techniques fall.

When conducting power supply identification, it is necessary to choose to test in a suitable environment to ensure that the test results are accurate and reliable.

The filtering efficiency of the DC power supply, or ripple factor, can be assessed using the effective value of the ripple voltage and the percentage of the DC output voltage. The ripple factor is an important indicator for evaluating DC power supplies.

Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp