The Integration of PLC and LED to Enhance Lighting System Intelligence

2024/8/13 10:38:01

Views:

LED lighting equipment has long become an indispensable part of our daily lives, covering almost every aspect of our work and living environments. Although LED lights are very common, their application actually involves the use of PLC technology.

1. PLC Control of LED Lighting Systems

With the support of PLC technology, a single LED light can emit warm white light, cool white light, or even any color in the spectrum, a capability that CFL lights currently cannot achieve. By utilizing PLC technology, LED lights not only become smarter but also enable better automation, control, and diagnostic functions. Since all lighting equipment needs to connect to power lines to convert electrical energy into light energy, many manufacturers are eager to use the PLC interface as the main communication and control link.

Power lines form the largest copper wire network globally, with power outlets available in every corner of homes and office buildings. Therefore, without the need to install new wiring, power lines can be used to achieve communication, ranging from basic color and brightness control to complex information exchange, such as color scenes and fade-in fade-out effects. Additionally, through advanced lamp discovery and binding mechanisms, users do not need to remember numbers or worry about accidentally turning off a neighbor's light, making it easy to establish a lighting control network with PLC functionality.

Supported by a bus topology, the power line network can not only manage all the lights in a single room but also control the lighting equipment throughout the entire home. This topology also allows a single light fixture to be controlled by multiple controllers, enabling the lights in one room to be controlled from another (e.g., turning off all the lights in the house from the bedroom). Furthermore, the controller can track all devices on the network in real-time, acting as a backbone server to achieve scalability and "plug-and-play" installation, allowing any newly added light fixtures to immediately become part of the network.

2. Application of PLC in LED Microwave Vacuum Drying Sterilizers

The core component of microwave equipment is the magnetron. PLC controls the intermediate solid-state relay to drive the step-up transformer, with an output voltage of approximately 6000V. The magnetron is an electron tube that generates microwave energy, consisting essentially of a diode placed in a constant magnetic field. The electrons in the magnetron interact with high-frequency electromagnetic fields under the influence of constant electric and magnetic fields, converting the energy obtained from the constant electric field into microwave energy, thus achieving the generation of microwaves. Depending on the working conditions, magnetrons can be classified into pulsed magnetrons and continuous wave magnetrons.

The magnetron consists of a tube core and magnetic steel (or electromagnet). The internal structure includes the anode, cathode, energy output device, and magnetic circuit system, with the interior of the tube maintaining a high vacuum state. Each component has its specific structure and function.

3. Combining PLC Bar Graph Displays with LED

PLC not only possesses the control functions of traditional relay control systems but can also expand input and output modules, particularly intelligent control modules, forming multifunctional comprehensive control systems. These systems integrate analog input and output control with modern control methods, achieving intelligent, closed-loop, and multifunctional control. Modern PLCs, with their high integration, powerful functions, strong anti-interference capabilities, and flexible configuration, have gained widespread popularity, playing an increasingly important role in the modernization of traditional industries.

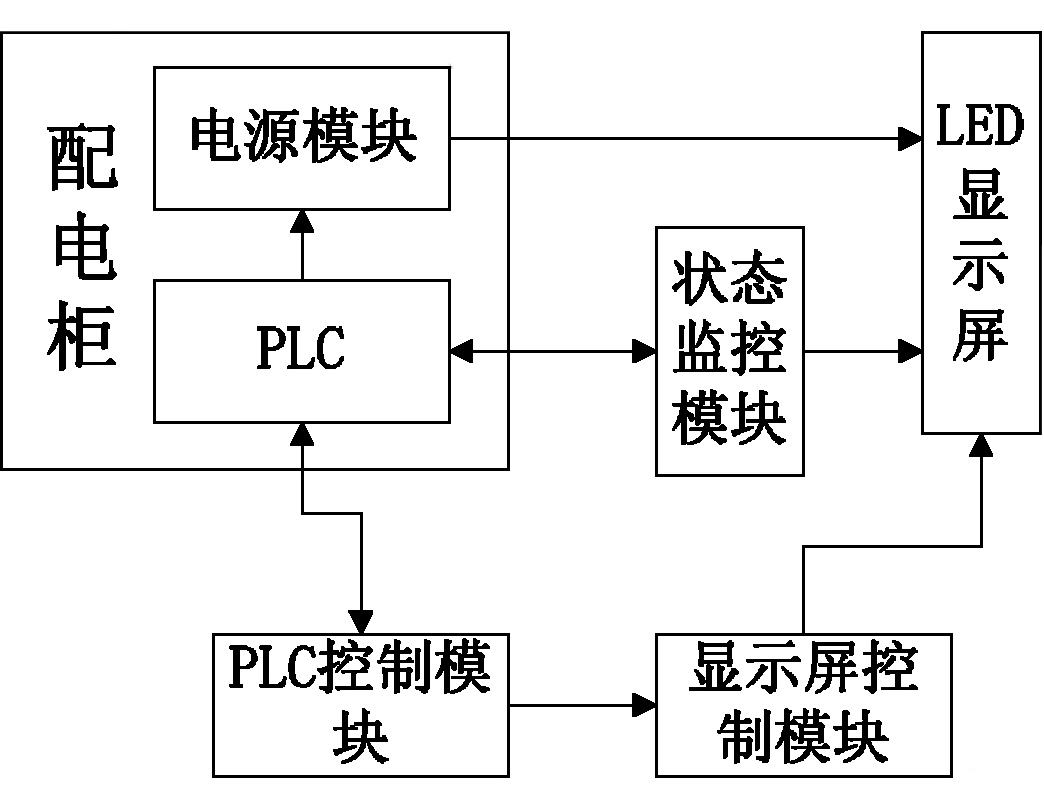

Although LED lights can easily provide display interfaces for control systems, the display interface designed by PLC is relatively simple, typically only showing status through indicator lights on the control cabinet or the LED lights of the PLC itself. For instruments such as level collection and control, this type of display interface is far from sufficient. Therefore, LED bar graph displays or PC display technology can be used to supplement the PLC display interface, providing a more intuitive and easy-to-understand display.

Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp