Exploring the future: EV battery design strategies and performance optimization

2024/5/27 11:25:49

Views:

Electric vehicle (EV) battery technology is constantly being updated and has become one of the key technologies for e-mobility. By 2022, the average cost of an EV battery pack will be $153/kWh, a 90% decrease from 15 years ago.

Looking ahead, the automotive industry expects that the demand for lithium-ion cells will grow at an annual rate of 33%, reaching 4,700GWh by 2030.

The difference in cost between EVs and internal combustion engine cars will get smaller as EV batteries become more affordable. However, growing costs for energy, raw materials, and the supply chain provide significant hurdles for the battery manufacturing industry.

With EV battery prices falling rapidly and demand growing, technological innovation is essential. The advancement of battery technology is essential to the growth of e-mobility.

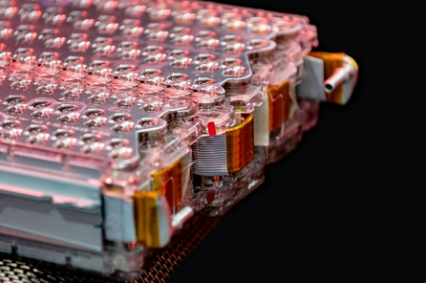

Battery pack, module, and cell performance design

EV battery cells can have a variety of forms. In essence, the initial development stages of the cell are similar. The selection and optimization of cell chemistry and materials must be finished by cell developers.

To achieve the range and fast charging expected by users, developers need to start at the cell chemistry level. The performance of different electrochemical combinations must be analyzed by cell developers in accordance with the battery performance criteria.

In order to determine whether various cell designs achieve design requirements, modern battery test labs need to be able to properly evaluate the real performance of the cells under test while managing a huge number of cells.

When designing and testing batteries, battery design managers have to take into account the various test parameters for various purposes, particularly if the cells are later integrated into modules or battery packs for power supplies. As a result, the necessary voltage, channel, and safety standards must be supported by the test environment.

Automation management is becoming more and more important in battery test labs

In addition to ensuring effective time and resource management, automated laboratory operations also facilitate test data tracking and traceability and increase test throughput.

If the test facility is large and there are many test sites, laboratory managers can use cloud-based laboratory operation management tools to manage and control the battery test operation status. They may also enhance the design by using the test data gathered from the gadgets that were put to the test.

Ensure consistent quality from the design phase through production

A new battery cell design moves into the rapidly expanding mass production stage once it is prepared for large-scale manufacturing. A McKinsey report states that if cell demand continues to grow at 30% per year, the global market will need to build another 90 Gigafactories at current capacity to meet the demand for vehicle electrification in the next decade.

America and Europe are following the footsteps of China and South Korea to manufacture electric vehicle batteries closer to the end market. These nations have made billion-dollar investments to increase Gigafactories' capacity.

There are many issues to be addressed before a Gigafactory is established, including location, budget, raw material acquisition, manufacturing system, and human resources. But our main concern is improving batteries starting at the cell level.

For high-volume manufacturing, throughput is a key indicator of production efficiency. The steps of the production of lithium-ion cells that take the longest are cell formation and aging. During the cell aging stage, manufacturers must measure the self-discharge rate of the cell in order to sort out bad cells with abnormal self-discharge characteristics.

It can take days, weeks, or even months for the cell's self-discharge characteristics to become apparent. But outdated techniques are very unfeasible in an industrial setting when time and money are critical.

These days, some manufacturers detect the self-discharge current inside the cell directly using a relatively recent constant potential measurement technique. This approach typically takes only a few hours to complete, saving time and space for quality checks.

New technologies are bringing faster-charging, higher-performance cells. These cells need to be cycled to assess their cycle life and the impact of charging rate on life.

To save energy, modern cell cyclers use regenerative power to feed the power generated during discharge back into the grid, reducing net energy consumption and operating costs.

Future-proof battery testing technology

As the electrification of vehicles continues, battery developers and manufacturers must get ahead of the curve in battery testing capabilities. They need to plan equipment to handle larger cell capacities, higher supply/consumption currents, and use regenerative power to reduce operating costs.

Some manufacturers are using modular "super test pods" to reduce the time and cost of battery testing while enabling rapid deployment based on demand. These innovations will help further advance battery development and production to power the adoption of electric vehicles.

Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp