Differential and Common Mode Filter Design Guide

2024/9/11 10:23:05

Views:

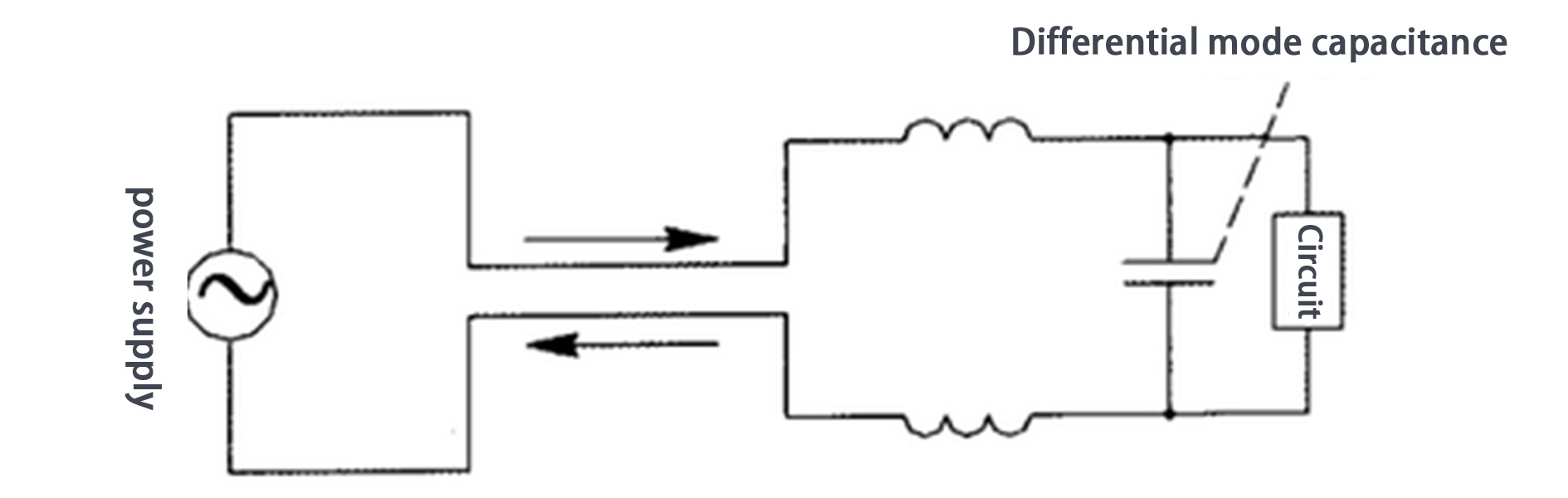

Low-frequency noise primarily originates from two types of filters: differential-mode and common-mode filtering. The purpose of differential-mode filtering is to reduce the noise caused by current returning along the power line loop. A capacitor is introduced between the power supply and ground to provide a low-impedance path, allowing the noise to return via this path without interfering with the measurement results. At the same time, an inductor is placed on the power line to prevent the noise from escaping the device. In commercial testing, an LISN (Line Impedance Stabilization Network) is typically used, which connects to the LISN through inductors and capacitors to provide a 50Ω source impedance.

In some cases, the noise is so weak that it can be diverted by a voltage divider consisting of a capacitor and a 50Ω resistor to transfer most of the noise. Ensure the ESR of the capacitor is suitable by choosing multilayer capacitors or metalized plastic capacitors.

Differential Mode Filter Design

A second-order LC circuit is used for differential-mode filtering. The noise characteristics are determined based on the noise spectrum before filtering, and the designed second-order filter must attenuate with a slope of 40dB/decade at a specific frequency. For example, if the differential-mode noise is 20dB at 100kHz, the filter's cutoff frequency can be set at 30kHz. LC parameters are selected by drawing a line with a slope of 40dB/decade.

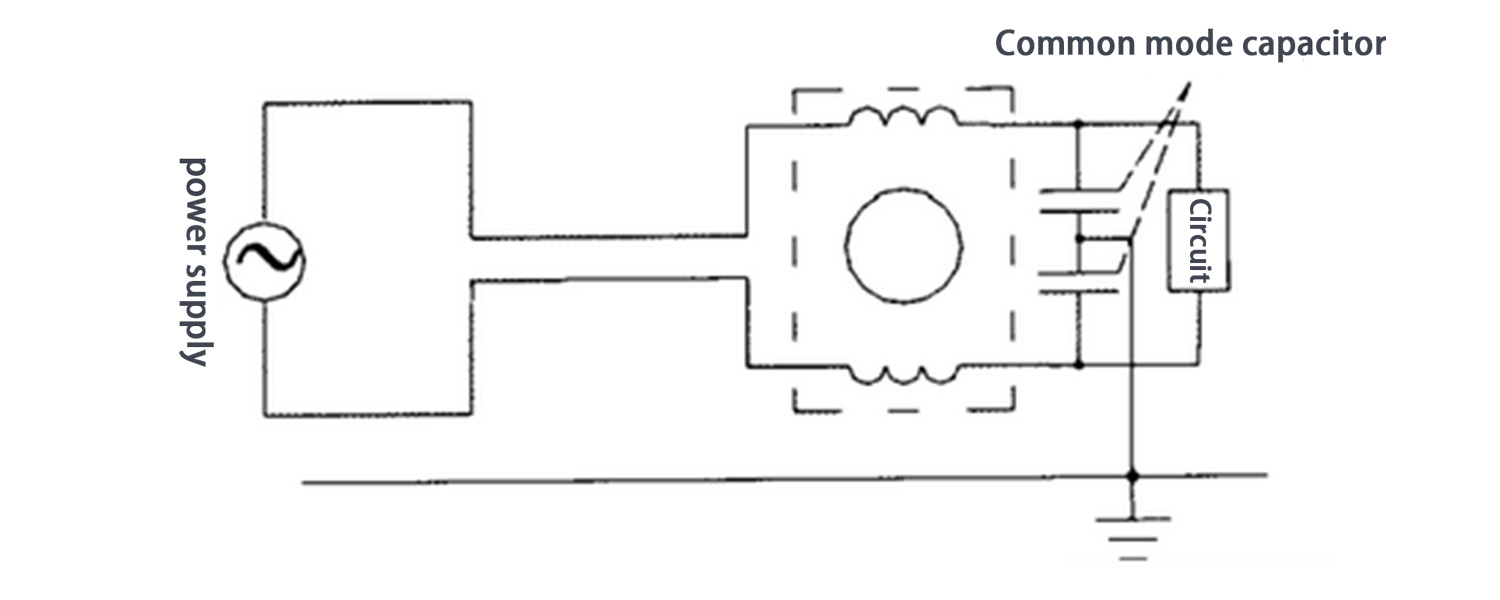

Common Mode Filter Design

The design of common-mode filters is simpler than that of differential-mode filters, with limited components, mainly common-mode capacitors and common-mode inductors. Common-mode capacitors (Y capacitors) direct noise from the power line to ground, while common-mode inductors provide balanced impedance, forming a high-impedance path to common-mode noise without affecting differential-mode currents. When selecting values, consider both the cost and design requirements of the capacitors and inductors.

Limitations of Capacitors and Inductors

Capacitors have frequency response limitations at high frequencies, especially electrolytic capacitors, where their equivalent series resistance (ESR) increases with frequency, causing them to behave more like resistors than capacitors at high frequencies. In general, ceramic or plastic capacitors are more suitable for EMI filtering. On the other hand, inductors also have performance limitations at high frequencies, as their parasitic capacitance may parallel the inductor, causing the inductor to no longer effectively suppress noise at certain frequencies. Two inductors can be connected in series to increase the inductance and reduce parasitic capacitance.

Varistors can also be part of the filter, typically used to absorb transient voltages on the power lines. Since varistors have small capacitance, be mindful of their leakage current's impact on circuit performance during application.

Integrated Design

Sometimes, combining common-mode and differential-mode filters can reduce costs, such as using a single core to achieve both functions. However, the design must consider the current and the saturation of the core. By adjusting the number of turns in the inductor winding, a higher inductance value can be achieved without increasing cost and size. For commercial designs, it is not recommended to use overly complex multi-stage high-order filters due to the challenges and complexity in production.

Design Considerations

For high attenuation requirements in the low-frequency range, such as 60-80dB, it is advisable to revisit the circuit layout, as leakage and crosstalk in PCB routing may affect filtering performance. Commercial filters are typically sealed in metal housings to prevent interference between circuits, which is also why they can achieve higher attenuation. You can use similar methods to enhance performance, but this can be costly.

Conclusion

Differential-mode and common-mode filters play a crucial role in suppressing power noise. By selecting the right components, designing circuits precisely, and thoroughly analyzing the noise spectrum, filter performance can be effectively improved to meet application requirements. Whether selecting capacitors or inductors, or determining the filter stages, it is essential to balance cost, size, and performance. Ultimately, an optimized filter design not only enhances circuit stability but also effectively reduces noise interference, ensuring reliable operation of the power system.

Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp