Unlocking the Secrets of Crystal Oscillator Packaging

2024/8/27 10:28:23

Views:

Gem oscillator bundling includes typifying the center component of the gem oscillator-the precious stone chip-using a casing or particular materials to improve its steadiness, assurance, and flexibility to natural variables. Bundling viably separates the gem oscillator from outside natural components, such as tidy, dampness, and vibration, guaranteeing it works ordinarily beneath different conditions.

Materials and Classification of Packaging

Selecting the right packaging material is crucial for different application needs. Common packaging materials include:

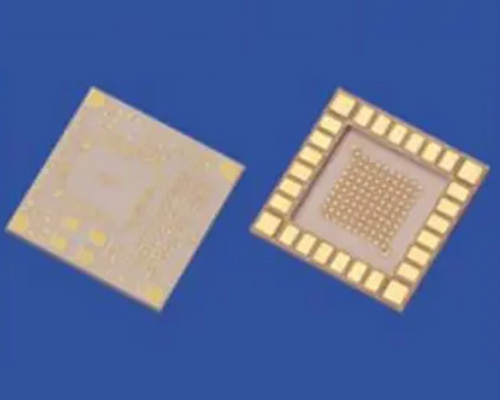

Ceramic Packaging: This type of packaging uses ceramic materials, which offer excellent high-temperature resistance and corrosion protection, making it ideal for use in extreme environments.

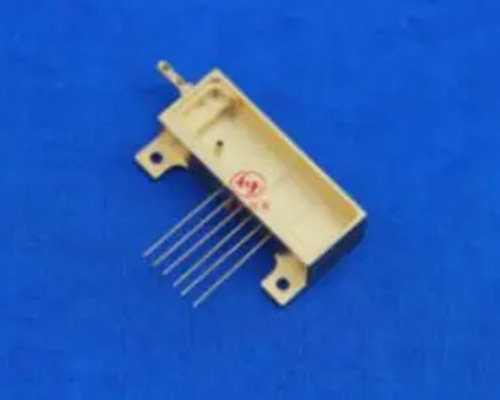

Metal Packaging: It provides good shielding and thermal conductivity, suitable for high-performance and high-reliability applications.

Plastic Packaging: Due to its low cost and simple manufacturing process, it is widely used in various electronic products, especially in large-scale production.

Glass Packaging: It has excellent sealing properties and mechanical strength, suitable for crystal oscillators requiring high precision and stability.

Based on the frame and auxiliary characteristics of the bundling, gem oscillator bundling can be primarily isolated into the taking after sorts:

Metal Shell Packaging: It employments a metal casing to typify the gem oscillator, giving great protecting and warm scattering, appropriate for applications with tall impedances and temperature prerequisites.

Plastic Packaging: This bundling employments plastic materials, with focal points such as lower taken a toll and moderately straightforward fabricating handle, making it broadly utilized in electronic items.

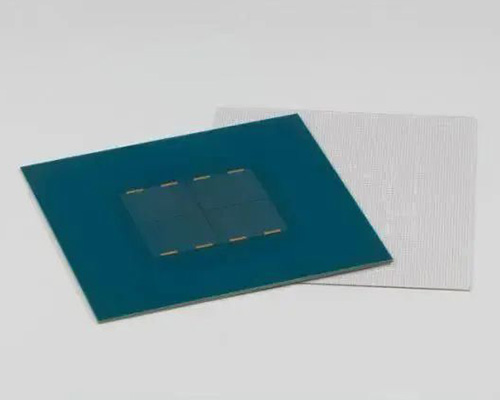

Surface Mount Gadget (SMD) Packaging: The precious stone oscillator is straightforwardly patched onto the PCB, reasonable for miniaturization and robotized generation needs.

Ceramic Packaging: Ceramic materials offer amazing solidness and bundling execution, making them perfect for high-frequency and high-temperature situations.

Process Flow of Crystal Oscillator Packaging

The process flow of crystal oscillator packaging typically includes several key steps:

Bundling Planning: Planning bundling materials and devices, and cleaning the surface of the precious stone chip to guarantee no pollutions meddled amid the bundling prepare.

Chip Testing and Screening: Conducting thorough testing and screening of the precious stone chip some time recently bundling to guarantee that as it were qualified chips continue to the following bundling handle.

Bundling Plan: Planning the suitable bundling sort and fabric based on the application necessities of the precious stone oscillator, and deciding the bundling structure and measurements.

Packaging Sealing: Using sealing glue or other materials to close the crystal oscillator, preventing external environmental influences on the internal components.

Packaging Fixation: Placing the crystal chip in the packaging material and securing it in the designated position to ensure stability.

Packaging Curing: After completing the packaging, curing treatment is performed to tightly bond the packaging material, improving shock resistance and environmental adaptability.

Packaging Testing: Conducting performance and quality tests on the packaged crystal oscillator to verify its stability and reliability.

Applications of Precious stone Oscillator Bundling Innovation

Precious stone oscillator bundling innovation is broadly utilized in different areas of the hardware industry, such as:

Communication Hardware: In gadgets like versatile phones, switches, and communication base stations, gem oscillator bundling innovation plays a vital part in clock and synchronization circuits.

Consumer Electronics: Devices such as smartwatches, digital cameras, and smart home equipment extensively use crystal oscillator packaging technology.

Automotive Electronics: The electronic control unit (ECU), navigation system, and in-car entertainment system of vehicles all require crystal oscillator packaging to ensure the accuracy of clock and timing circuits.

Computers and Networking Equipment: Crystal oscillator packaging is also indispensable in the clock and timing circuits of computer motherboards, networking devices, and servers.

Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp