PWM Pulse Width Basics: Enhance Your PWM Control

2023/4/15 18:22:14

Views:

Pulse Width Modulation (PWM) is a versatile technique widely used in various fields of electronics and control systems. PWM is an proficient strategy for controlling control to electrical gadgets, counting engines, LEDs, and other actuators, by changing the width of the pulse in a flag. This article will plunge profound into the essentials of PWM pulse width, investigate its applications, and illustrate how it can be upgraded for way better control in frameworks like Arduino.

What is PWM?

Table of Contents

- What is PWM?

- Understanding Pulse Width Modulation

- PWM Signals and Applications

- Arduino Pulse Width Modulation and PWM Control

- Advanced Concepts in PWM

- Conclusion

- Commonly Asked Questions

What is PWM?

PWM Definition

At its center, Beat Width Balance (PWM) may be a method that controls the control conveyed to a load without shifting the voltage or current. Rather than altering the normal voltage connected to a gadget, PWM alters the obligation cycle of the flag. The duty cycle is the rate of time the flag is within the "on" state amid each cycle. The higher the obligation cycle, the more control is conveyed to the load, and bad habit versa.

For case, a 50% obligation cycle in a PWM signal implies that the signal is on for half of the time and off for the other half. In the event that you increment the obligation cycle to 75%, the signal is on for a longer length inside the cycle, expanding the normal control conveyed to the load.

PWM can be utilized in many applications, from engine speed control to darkening Driven lights. By altering the obligation cycle, you'll be able finely control the power delivered to these gadgets.

Understanding Pulse Width Modulation

PWM Pulse Width Modulation Explained

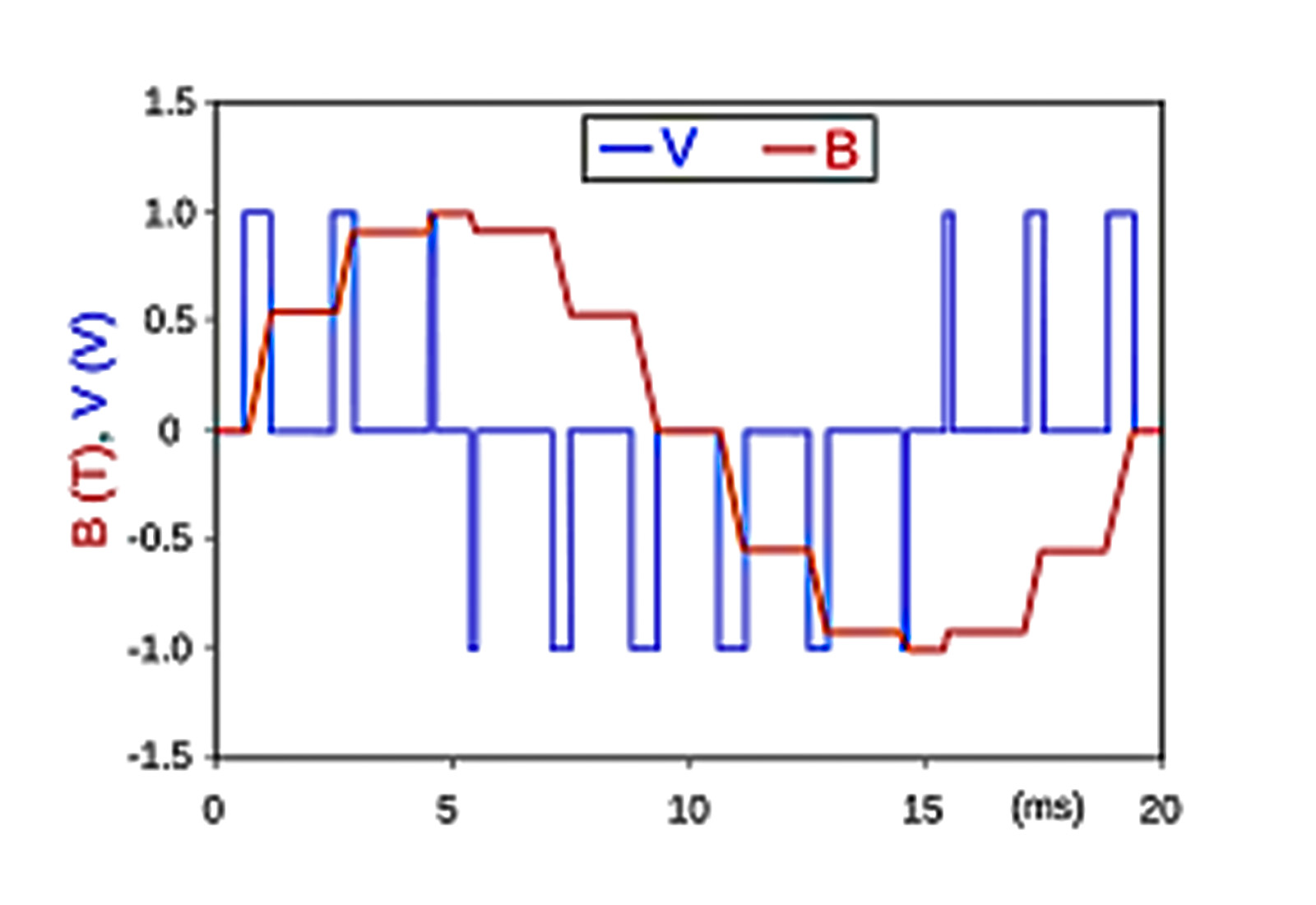

In PWM pulse width tweak, the width of each pulse inside a occasional flag is shifted to encode data or control the control yield. The term "width" here alludes to how long the pulse remains tall inside each period. The period is the time between the begin of one pulse and the starting of the following. The more noteworthy the width of the pulse, the more vitality or data is transmitted amid each period.

For occasion, in motor control, expanding the pulse width permits more current to stream through the motor, driving to higher speeds. Alternately, diminishing the beat width diminishes the current and moderates the motor down.

Pulse Duration Modulation and Pulse Wave Modulation

PWM is closely related to other modulation methods such as pulse duration modulation (PDM) and pulse wave modulation. These are varieties of PWM that control diverse angles of the pulse to realize comparative comes about.

In pulse duration modulation, the term of the pulse is tweaked whereas keeping the sufficiency consistent. The key distinction is that PDM straightforwardly tweaks the pulse length to encode data, whereas PWM centers on the width and redundancy of pulses. Pulse wave modulation refers to the generation of a series of pulses, which can also have varying widths, in contrast to continuous analog signals.

Both of these techniques, like PWM, are used in control systems, telecommunications, and power regulation.

PWM Signals and Applications

Pulse Width Modulated Signal Characteristics

A pulse width balanced flag is characterized by its recurrence and obligation cycle. The recurrence alludes to how frequently the flag rehashes per second, whereas the obligation cycle characterizes how much of each cycle the flag spends within the tall state. These two components specifically impact the behavior of a load, such as an electric engine or an LED.

For example, a 1 kHz PWM signal (1000 cycles per second) with a 20% duty cycle means the signal stays high for 20% of each cycle and low for the remaining 80%. Adjusting these parameters allows for precise control of the connected load.

The Importance of Pulse Width in Control Systems

The pulse width signal is crucial in deciding the sum of control conveyed to gadgets in control frameworks. For occasion, in a motor control circuit, the more extensive the pulse, the more vitality the motor gets, coming about in speedier turn speeds. Narrower pulses reduce the power delivered, slowing the motor down. This level of control makes PWM a crucial tool in applications that require fine-tuning, such as robotics and audio amplifiers.

PWM is also important for power efficiency. Since the control is conveyed in pulses, instead of ceaselessly, there's less vitality misplaced as warm, which is especially profitable in battery-operated gadgets or frameworks where Power consumption must be minimized.

Arduino Pulse Width Modulation and PWM Control

Arduino and PWM

PWM is broadly utilized in Arduino ventures for controlling servos, engines, and LEDs. By using Arduino pulse width modulation, you can vary the power delivered to an output pin without needing complex circuitry. This is especially helpful in hobbyist and educational projects where precise control is required.

Arduino's built-in PWM usefulness permits clients to produce beat width tweaked signals on particular pins (ordinarily stamped with a "~" on the board). By changing the obligation cycle of these signals, you'll control the speed of a engine, the brightness of an Driven, or indeed tweak a tone on a buzzer.

Enhancing Control with PWM on Arduino

When using Arduino pulse width, you'll be able upgrade control by altering the obligation cycle dynamically in your code. For occurrence, you'll utilize a potentiometer to differ the obligation cycle of a PWM flag, which might be utilized to control the brightness of an Driven or the speed of a engine in genuine time.

Utilizing progressed methods like PID (Proportional-Integral-Derivative) control can too make strides the accuracy of PWM control in frameworks that require criticism, such as adjusting robots or temperature control frameworks.

Practical Applications of PWM with Arduino

Some typical Arduino projects involving PWM include:

Module PWM for Expanding Control

In more advanced projects, you might want to extend the number of PWM outputs available on your Arduino or similar platform. This is where a module PWM can be useful. By adding external modules, you can significantly increase the number of PWM-controlled devices in your system. For example, you can control more LEDs, motors, or other actuators simultaneously, giving your project more flexibility and scale.

Advanced Concepts in PWM

Frequency vs. Duty Cycle

Whereas the obligation cycle controls the sum of power conveyed to a load, the recurrence of the PWM flag can moreover have critical impacts. In applications such as Motor control, a high-frequency PWM flag can lead to smoother operation and less capable of being heard clamor, whereas lower frequencies might cause the Motor to murmur or vibrate

When choosing a PWM frequency, consider the characteristics of your load. For LEDs, a higher frequency can prevent visible flickering. For motors, it's crucial to balance the frequency to avoid resonance issues.

Controlling Analog Devices with PWM

In spite of the fact that PWM produces a advanced flag (on or off), it can be utilized to control analog gadgets. This can be often done by smoothing the PWM flag employing a low-pass channel. The sifted flag approximates a consistent analog voltage, making it appropriate for applications like sound control, diminishing radiant bulbs, or driving analog meters.

Conclusion

Pulse Width Balance (PWM) is an basic procedure for controlling control and signals in different electronic applications. From fundamental Driven darkening to complex motor control frameworks, understanding and improving PWM control permits you to attain exact and productive operation. Whether you are working with pulse duration modulation, pulse wave modulation, or designing systems with pulse width modulated signals, the ability to manipulate the width of the pulse gives you unparalleled control over your devices.

With platforms like Arduino, Arduino pulse width modulation makes it easier than ever to implement PWM in projects. Whether you're controlling motors, LEDs, or servos, PWM allows you to fine-tune the behavior of your devices with minimal hardware overhead. Growing your information of PWM and utilizing extra module PWM choices can advance upgrade your project's complexity and capability.

By understanding the pwm definition and how to apply it to different control frameworks, you'll can unlock the total potential of this flexible tweak procedure.

Commonly Asked Questions

Why is "PWM pulse width" highly searched?

PWM is widely used for controlling devices like motors and LEDs. As DIY electronics and automation projects grow, more people need to understand and optimize pulse width, increasing search demand.Why does "PWM control" have a high search volume?

PWM control is essential for tasks like motor speed regulation and LED dimming. As platforms like Arduino become popular, interest in learning PWM control has surged.Why is choosing the correct PWM frequency for LED flickering frequently searched?

Low PWM frequencies cause visible flickering in LEDs. Many users search for optimal frequency settings to avoid this issue.Why is "PWM pulse width" often searched with motor control?

PWM pulse width affects motor speed. It's crucial in robotics and automation, so users frequently seek information on optimizing motor performance.Why has the search volume for Arduino PWM control increased?

Arduino's growing popularity has led to a rise in searches for how to use PWM to control devices like motors and LEDs in various projects.Related Information

-

-

Phone

+86 135 3401 3447 -

Whatsapp